Cemented Carbide Choke Valve Stem

Description

Basic Info

| Model NO. | Seeder_01644 |

| Service | Customize ODM OEM |

| Key Word | Choke Stem and Seat |

| Industry | Oil & Gas Industry |

| Transport Package | Standard Package / Customize Packing |

| Trademark | Aseeder |

| Origin | China |

| Production Capacity | 3000 PCS Per Month |

Product Description

We can customized choke parts based on customer's drawing and material requirement , below is our choke seat and stem parts with stock material support fast delivery, if you want a customized choke parts welcome to contact us for details.

Choke bean is often used in the positive choke valve for controlling the flow, Aseeder choke bean is same as Cameron type H2 big john choke bean, body Material: 410SS, lined with Tungsten Carbide (C10 or C25) , to protect them from corrosive and abrasive wear.

On one side of the choke manifold, calibrated choke beans are used to control flow rate through the fixed choke box. Each bean is a specific diameter, usually in graduations of 1/64-132 inch, Depending on the type of equipment used, the size of the choke bean can be as large as 3 inches.

We can do the QPQ treatment on the body of choke bean, to enhance the surface hardness

1. Product Name & Description

| Name | Description | Material | Remark |

| 3/4"Seat | CHOKE SEAT, 3/4" ORIFICE 10K/15K | 410+tungsten carbide ZY06-G | support fast delivery |

| 1"Seat | CHOKE SEAT, 1" ORIFICE 10K/15K | 410+tungsten carbide ZY06-G | support fast delivery |

| 3/4"-1"Stem | CHOKE STEM (TSI-BSS),3/4"-1" MAX 15M LONG | 304+tungsten carbide ZY10X | support fast delivery |

| Others | Support customized design | per customer's requirement | optional |

2. Choke seat and choke stem dimentions

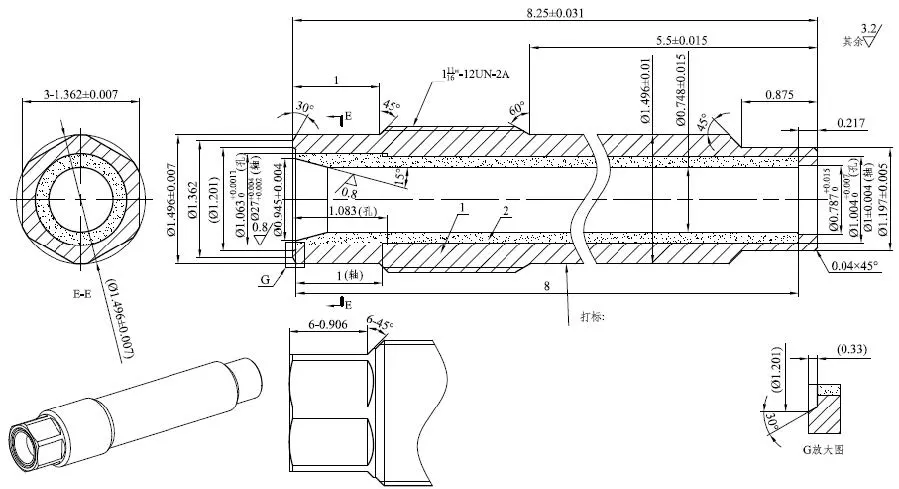

1) 3/4" choke seat print & dimentions

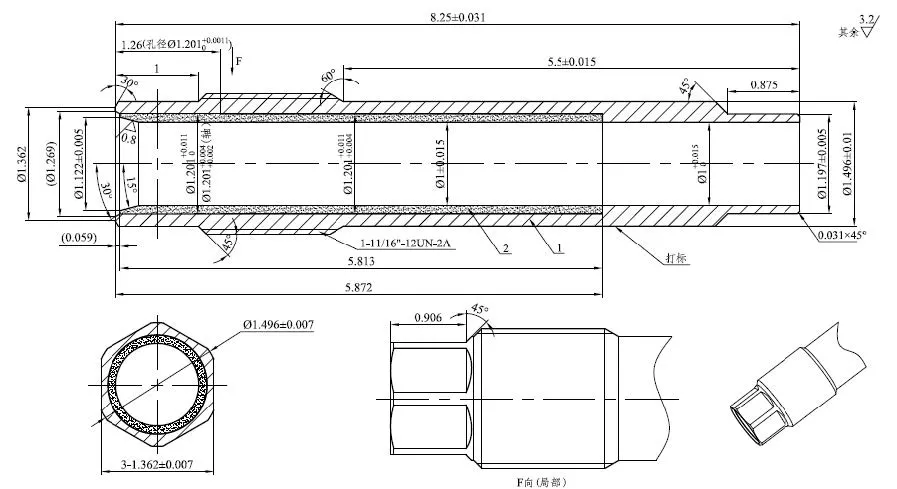

2) 1" choke seat print & dimensions

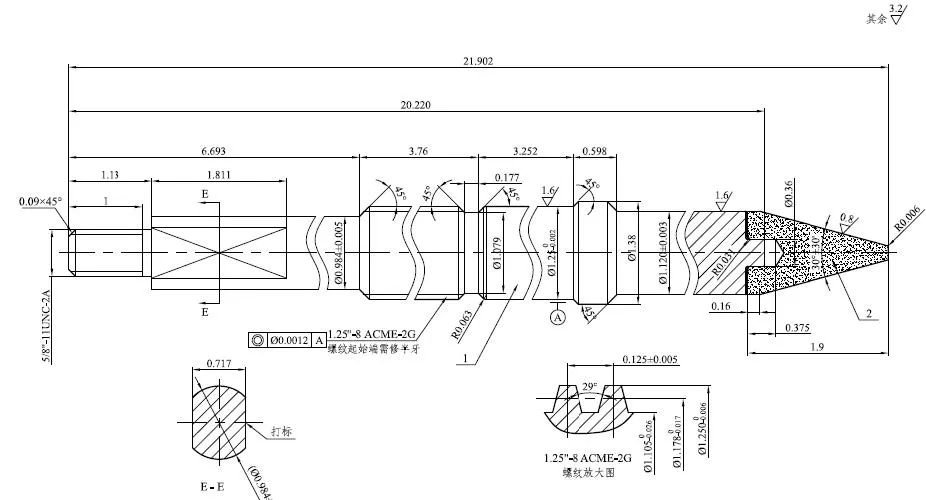

3) 3/4"-1"Stem Print & Dimensions

3. Chemical composition of 410 steel

| Chemical Composition(%) | C | Si | Mn | P | S | Cr |

| Acceptable range Min | 0.08 | / | / | / | / | 11.5 |

| Acceptable range Max | 0.15 | 1 | 1 | 0.04 | 0.03 | 13.5 |

| Measured | 0.12 | 0.47 | 0.57 | 0.012 | 0.007 | 12.5 |

4. Mechanical properties of 410 steel

| Test Item | Unit | Required | Measured | Conclusion | |

| Tensile Test | Tensile Strength | MPa | ≥690 | 714 | OK |

| Yield Strength | MPa | ≥550 | 576 | OK | |

| Elongation | % | ≥15 | 25 | OK | |

| Reduction of Area | % | ≥45 | 69 | OK | |

| Hardness | HB | HB | 207-235 | 228 | OK |

5. Physical properties of carbide ( SEED grade ZY06-G )

| Test Item | Unit | Required | Measured | Conclusion |

| TRS | N/mm² | ≥2800 | 3106 | OK |

| Cobalt | % | 5.5-6.5 | 6.0 | OK |

| Density | g/cm3 | 14.65 to 15.05 | 14.95 | OK |

| Hardness | HRA | 91.3-92.3 | 91.9 | OK |

6.Chemical composition of 304 steel

| Chemical Composition(%) | C | Si | Mn | P | S | Cr | |

| Acceptable range | Min | / | / | / | / | / | 18 |

| Max | 0.08 | 1 | 2 | 0.045 | 0.03 | 20 | |

| Measured | 0.052 | 0.4 | 1.1 | 0.034 | 0.001 | 18.16 | |

7.Mechanical properties of 304 steel

| Test Item | Unit | Required | Measured | Conclusion | |

| Tensile Test | Tensile Strength | MPa | ≥515 | 565 | OK |

| Yield Strength | MPa | ≥205 | 250 | OK | |

| Elongation | % | ≥40 | 56 | OK | |

| Reduction of Area | % | ≥50 | 74 | OK | |

| Hardness | HB | HB | ≤235 | 205 | OK |

8.Physical properties of ZY10X

| Test Item | Unit | Required | Measured | Conclusion |

| TRS | N/mm² | ≥3150 | 3701 | OK |

| Cobalt | % | ≥10.0 | 10.0 | OK |

| Density | g/cm3 | 14.25 -14.65 | 14.41 | OK |

| Hardness | HRA | ≥90.2 | 91.8 | OK |

Prev: Brass Ball Valves Bronze Extended Stem for American Market

Next: Silicon Car Wheel Nut Cover Car Wheel Nut Cover Nuts Wheels Racing Car Wheel Nut Cover

Our Contact