19mm Silicone Car Wheel Hubs Lug Nut Screw Caps

Description

Basic Info

| Model NO. | Wheel Hub Cover |

| Material | Silicone |

| Type | Wheel Hub |

| Drive Wheel | FWD |

| Wheel Hub Diameter | 16-20" |

| Wheel Accessories | Wheel Spacer |

| Spoke Type | Equal Diameter Spoke |

| Certification | ISO, CE |

| Wheel Hub Brand | All Brand Accept |

| Sample | Available |

| Package | Carton and Customized |

| Size | Standard or Customized |

| Transport Package | Customized Package |

| Specification | Customized Specification |

| Origin | China |

| Production Capacity | 500000PCS/Month |

Product Description

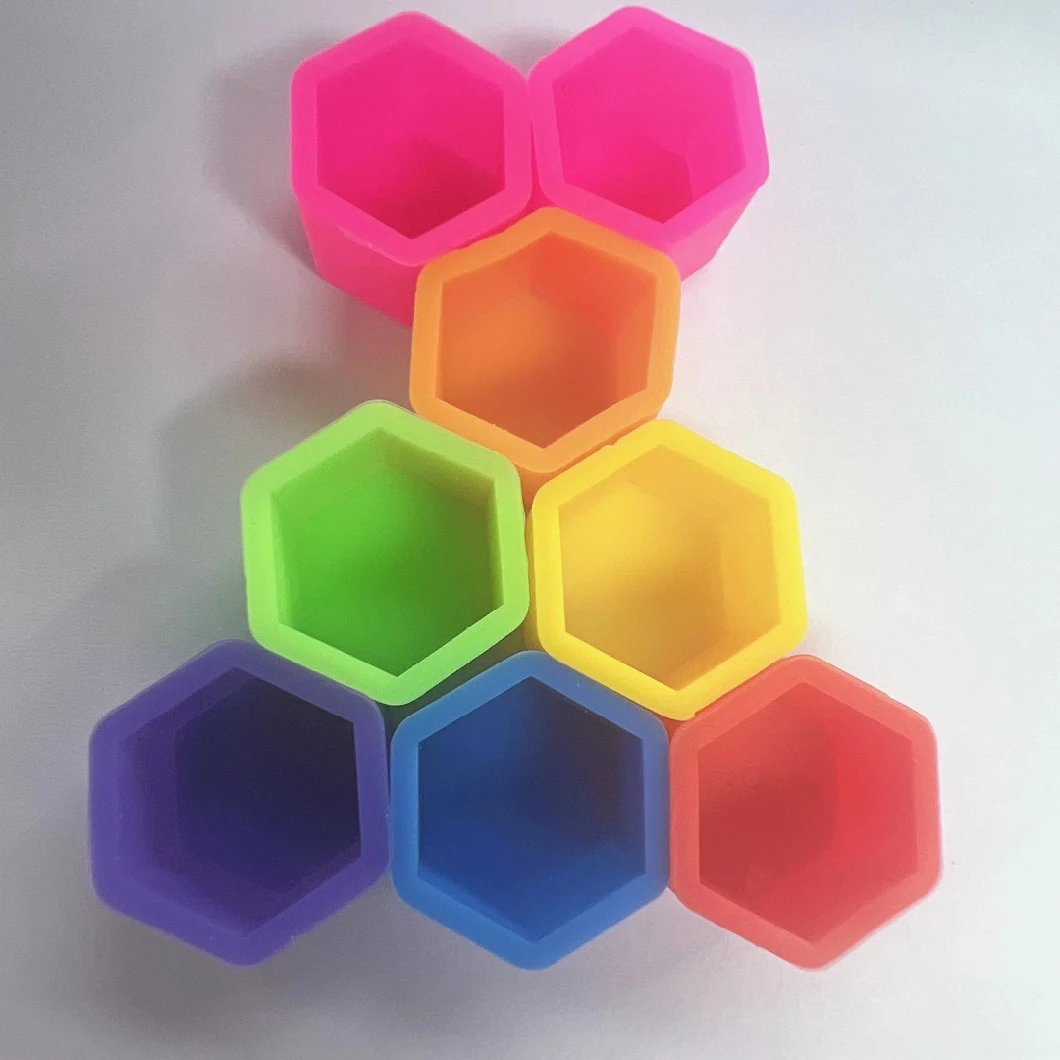

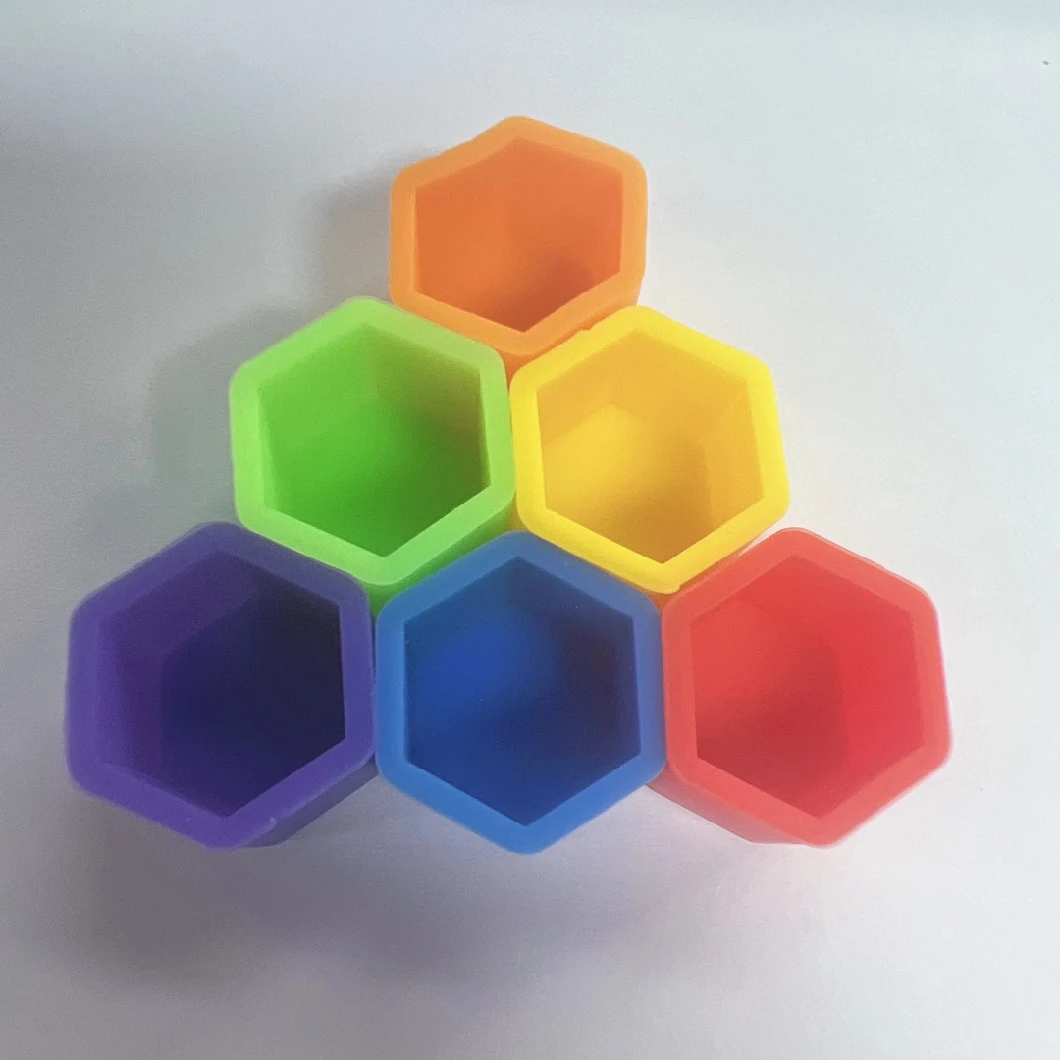

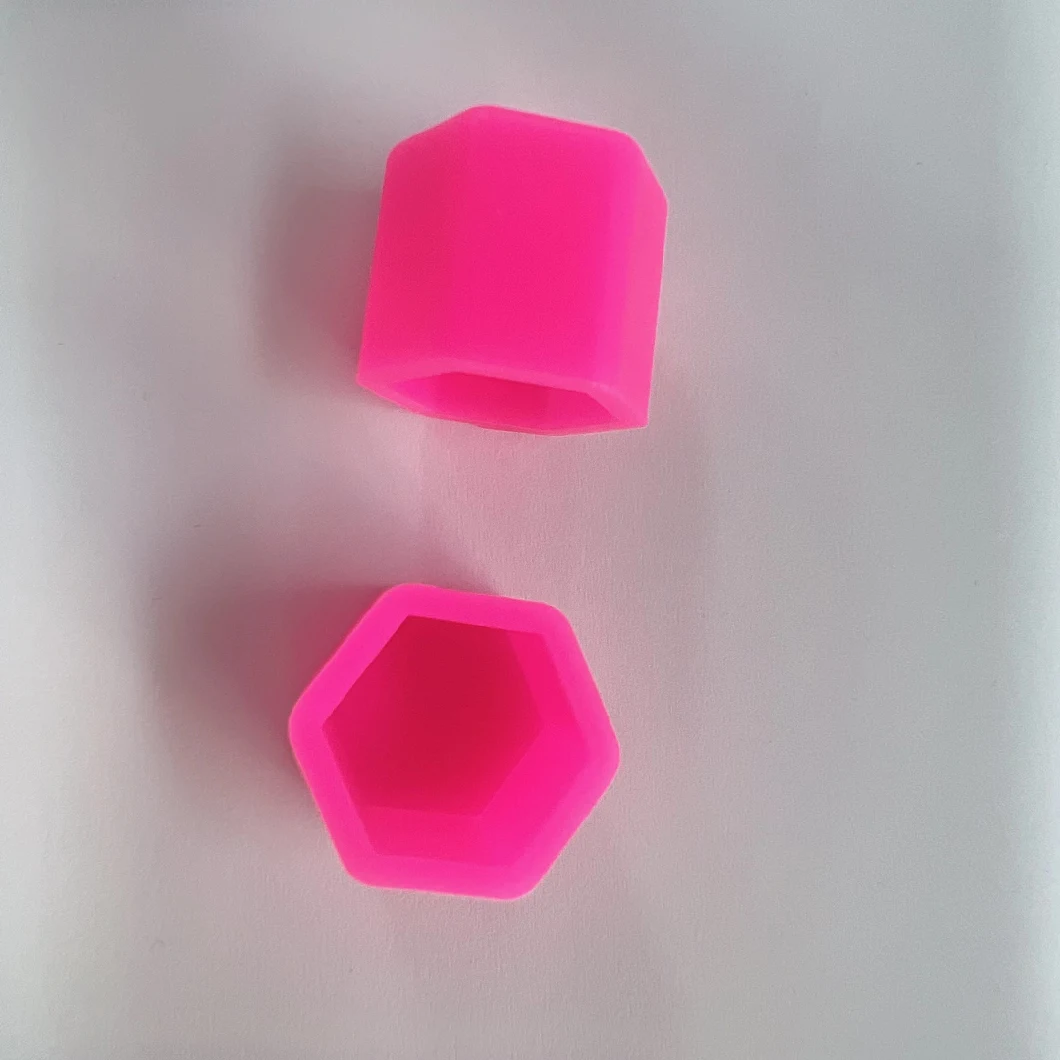

Detailed Photos

| Brand Name | Silicone Foam Molding Products(Customized) | |

| Material | Silicone rubber | |

| color | Customized colors | |

| Place of Origin | China | |

| Working Temperature | - 60°C to +260°C | |

| Features | Can bear High temperature and High Pressure | |

| Size | As your requirement | |

| Application | Water dispenser,Fish tank ,Medical equipment, Coffee machine, Food and Beverage, Air and Gas lines, Chemical lines, Laboratory and reserch, Protective jacketing, Water and Fluid lines. | |

Feature

1. The flexibility and anti-aging capability is very good.

2. Rubber seal could stop air, water and dust enter the machine system, which could protect the

machine or parts to be healthy and working well.

Application

Widely used in various kinds of industries, including auto .parts, doors, windows, containers,

machines, control cabinets, construction, ship industries etc.

| Packing Type | Usually packed in roll, 50-100 meter/roll; or customized according to customer requirement |

| Packing Material | Inner PE film wrapped over each roll + outer woven bag ( 3~4 rolls/bag) or outer carton box (one roll/carton box), palletized for extra reinforcement if necessary |

| Shipping Marks | Neutral packing with printed marks. |

| Freight | Sea (FCL & LCL) or air freight |

| Delivery Time | Shipped out within 3-10 days after receiving PO and payment(for new customer). |

Shenzhen Hongweixin Technology company founded in 2015Y, the factory located in Shenzhen Longgang district. The company specializes in the production of silicone tube, silicone strip, silicone foam pad and various specifications of silicone molded parts and other silicone products, widely used in food, medicine, daily chemical, hardware and other industries.

Embracing change and following the trend, Shenzhen Hongweixin established the New Energy Business Division in March 2021, which is a subsidiary of Shenzhen Hongweixin Technology Co., LTD. It is a high-tech enterprise integrating product research and development, production, sales and after-sales service. With the keen market sense of smell and strong sense of crisis management, based on the unique market advantage, Shenzhen Hongweixin is facing a new fasting development, and gradually into a global competitive and influential ribbon cable series products (including wiring harness, terminals, test board, etc.).

FAQQ1: Do you have your own factory?

A:Yes, we have our own factory established more than 12 years.Q2: Silicone seems to be more expensive than other rubber, why is this?

A: Silicone is more expensive than most rubber types because it is a speciality high performance polymer with outstanding qualities. It is made in relatively low quantities and requires expensive and complicated primary manufacturing facilities.

Q3: What is the difference between 'curing' and 'vulcanization'?

A: The terms curing and vulcanization essentially describe the same thing - the transformation of the polymer into a cross-linked rubber.Q4: Why is silicone used in food applications?

A: Silicone rubber is among a number of rubber types that can be used in contact with food. It has the advantage of being a low taint non-toxic material.Q5: Do you provide sample? Is it for free or not?

A: Yes, if we have it in stock we can offer the sample for free, while you need to pay for the freight cost to your country.Q6: When can you launch delivery after I placed order?

A: If there is stock, 2-5 days; if not, 15-30 days depends on the quantity.

Our Contact